What exactly is ‘dB loss?’

In fiber optics, data is transmitted via light pulses sent through thin strands of glass, with the...

400 South Salina St. Suite 201,

Syracuse, NY 13202

BLOG

In fiber optics, data is transmitted via light pulses sent through thin strands of glass, with the...

In fiber optics, data is transmitted via light pulses sent through thin strands of glass, with the goal of converting those pulses into useful information. Performance is measured in decibels (dB)1, similar to how sound is measured. This indicates how much power the light has as it moves through the cables.

Since the real goal is to transmit 100% of the data, the most useful metric is how much of it gets lost in transit. This is called dB loss.

In order to measure dB loss, an “insertion loss test” is performed. This test uses a light source and a power meter to measure how much of the light is received. Too much light loss will lead to a failure and signifies that the cable does not meet industry standards.

Considering that the light being transmitted directly represents valuable data, losing light equates to losing information. This creates potential operational issues and loss of money.

The time to think about dB loss is before installation, when purchasing the equipment and connective cabling.

While price is often the primary determinant when evaluating equipment, it should not be the only one. Cables built to provide the lowest possible dB loss will help ensure the best data transmission. Therefore, your best value should feature a combination of affordability and quality.

However, even after procurement, it is easy to mistakenly degrade your fiber optics’ capability. One issue is end-point contamination.

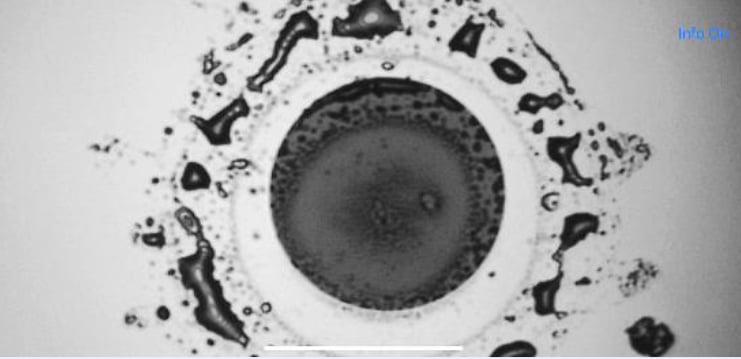

Touching the connector ends can severely contaminate the transmission of light by smearing the glass ends with oil and dirt. It’s similar to putting your fingerprints on the lens of a camera. (The image at right shows the contamination of an end face touched by a human finger.)2

Other contamination, like dirt, dust, and moisture can be introduced before the cables are plugged in. Therefore it is important to use a scope to inspect the cable end faces, and a special cleaner to ensure a pristine surface just before connecting.

Unfortunately, people often assume that the fiber optic cable is useless or defective when it only needs to be cleaned. Rather than inspect and clean, they mistakenly discard and replace.

Remember that the power of your fiber cable is in its ability to cleanly transmit a vital asset – information. A mediocre cable or mishandling of a good one can easily devalue your data.

It is important to take the necessary time to evaluate and properly install quality fiber optic cables to avoid the hassles of loss of data and network failure.

Quality cables with low data loss will help you meet your loss budget as you design a structured cabling environment. As each connection is a point of loss, a tight connection with a healthy, quality cable will ensure you maximize your ROI and don’t step out of the budget standards. Outside budget standards, data movement can become unreliable, or even breakdown.

Many organizations consider their data to be their most valuable asset and the quickest way to lose it is with poor data transmission. Take steps with your next data center design to ensure transmissions remain smooth and timely.

Introduction: A New Chapter in Optical Connectivit

Low-loss fiber connectivity is essential for...

Starting a data center hardware upgrade is a...

Why does the gauge matter in my network’s racks?...

High dB loss in fiber optic cabling...

Let’s look at the construction of fiber optic...