Starting a data center hardware upgrade is a significant undertaking, but if cabling has been left until the last minute, some...

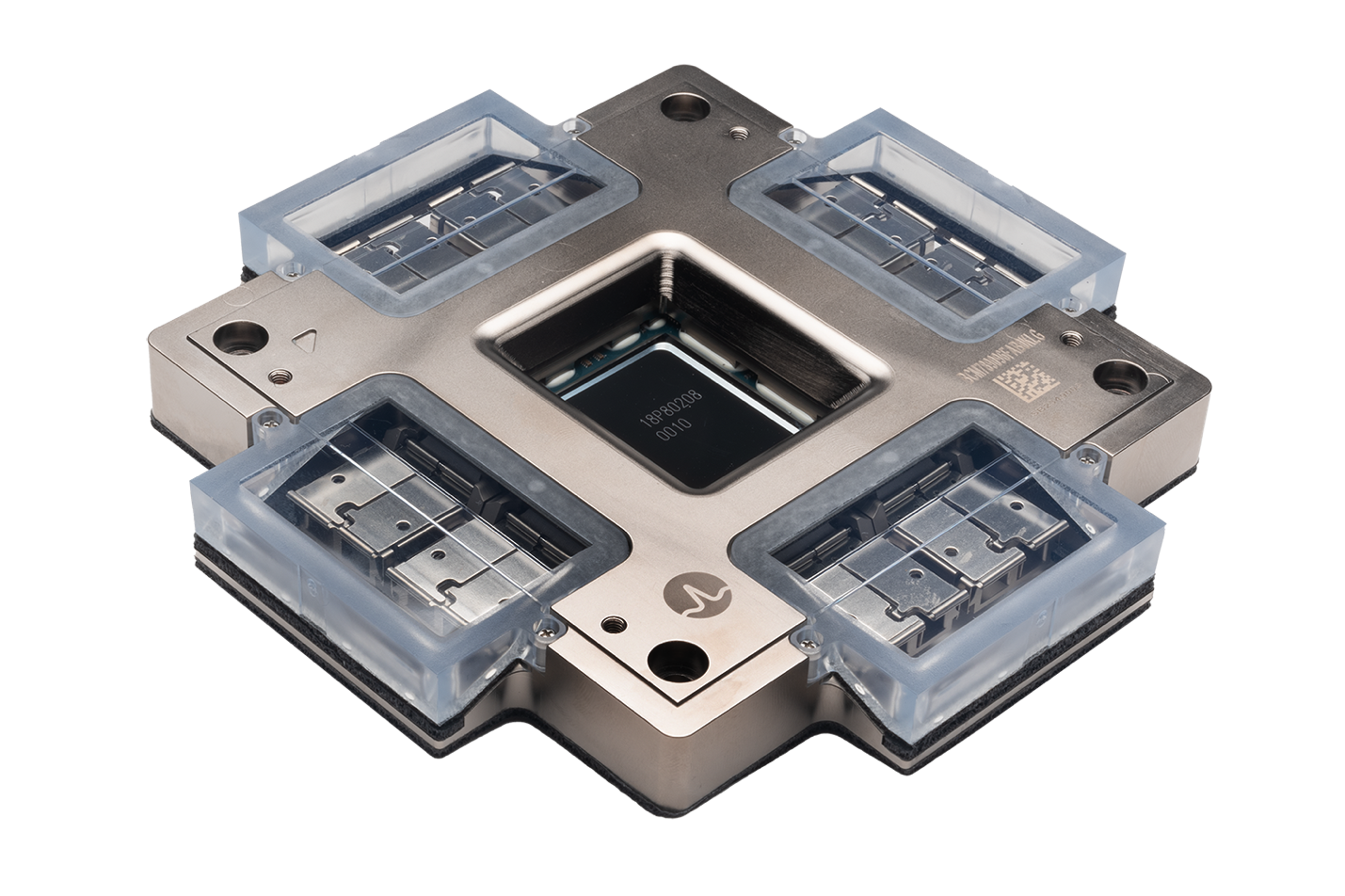

Starting a data center hardware upgrade is a significant undertaking, but if cabling has been left until the last minute, some key considerations can ensure you still achieve a successful outcome. The first step is to quickly assess your cabling needs relative to the new hardware specifications. With the shift toward high-density and high-bandwidth equipment, such as the latest switches, servers, and storage systems, ensure that your existing infrastructure supports these upgrades. Fiber and copper cabling types, connector standards (like MPO/MTP®), and compatibility with higher-speed transceivers are critical to evaluate. Choosing cabling that meets or exceeds your anticipated performance requirements will minimize the chance of bottlenecks or network downtimes later on.

Additionally, confirm lead times for the cabling components you need. Last-minute orders can be subject to delays, especially with the current demand for high-performance data center components driven by AI and hyperscale data center expansions. You may need to consider alternative suppliers or expedited shipping options. It can also help to consult with a structured cabling expert to quickly design a layout that optimizes space and airflow, making the most of your data center's existing footprint while supporting future upgrades. Prioritizing careful planning for cabling in the final stages will ultimately save time, reduce the risk of errors during installation, and help ensure that the upgraded hardware performs to its full potential.

To avoid confusion and delays during installation, careful organization of your cabling shipments and setup is essential. Start by organizing your cable orders so that each rack’s cables are packed and labeled separately. This simple step can drastically reduce the time spent sorting through cables during installation and eliminates the frustration of misplacing essential components. Pre-labeling cables with destination identifiers, such as rack or port numbers, is another effective approach. This not only accelerates the installation process but also aids future troubleshooting by making it clear where each cable should connect.

Additionally, configuring your fiber patch panels with future needs in mind can help prevent waste and ensure a more flexible setup. When setting up patch panels, consider adding extra capacity to accommodate anticipated growth and changes. Modular patch panels, for example, allow for easy expansion without replacing the entire setup. This foresight will make it easier to adjust to future upgrades while keeping your cabling environment organized and efficient. Proper planning at this stage helps ensure the cabling is as streamlined as possible, ultimately reducing the risk of delays, and enabling a smoother hardware upgrade process.

Recent Posts

Introduction: A New Chapter in Optical Connectivit

Low-loss fiber connectivity is essential for...

Starting a data center hardware upgrade is a...

Posts by Tag

- data center (12)

- Fiber Optic Cables (11)

- Cabling (7)

- NETWORKING (6)

- Structured Cabling (6)

- Fiber Optic Cabling (5)

- Fiber Cable (4)

- Networking Cables (4)

- Fiber Cables (3)

- Hardware Security (2)

- IT Infrastructure (2)

- Port Replication (2)

- Sustainability (2)

- AI (1)

- Brocade (1)

- Carbon Offsetting (1)

- Data Security (1)

- FCOE Works (1)

- ICLs (1)

- IT Equipment (1)

- IT Network (1)

- IT infrastructures (1)

- POE (1)

- Switches (1)

- Tapped Holes (1)

- data centers (1)

- hardware (1)

- infrastructure (1)

- storage (1)

- strategy (1)

Popular Posts

Why does the gauge matter in my network’s racks?...

High dB loss in fiber optic cabling...

Let’s look at the construction of fiber optic...