Let’s look at the construction of fiber optic cables, which are one of the simplest yet most powerful tools in data transmission...

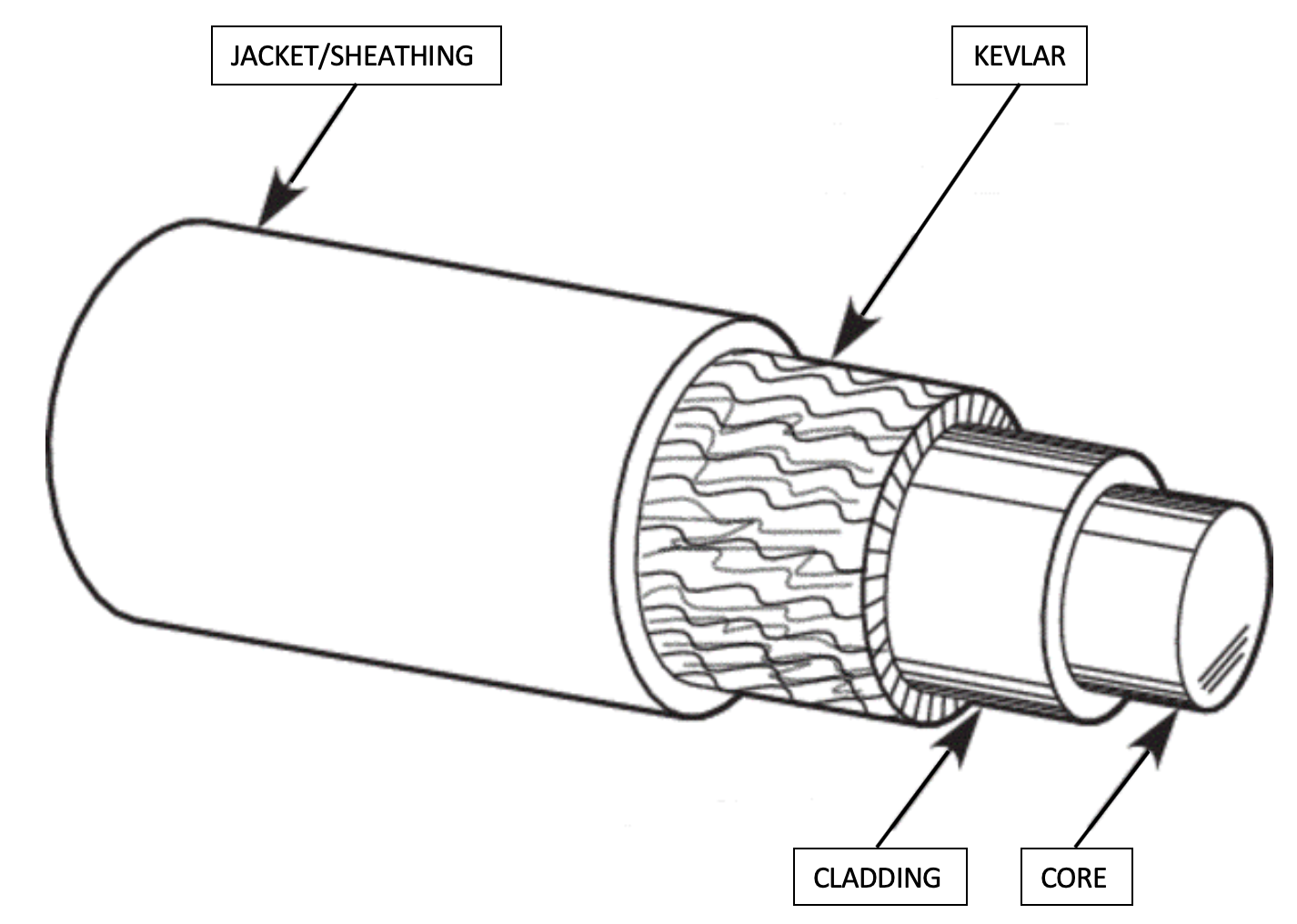

Let’s look at the construction of fiber optic cables, which are one of the simplest yet most powerful tools in data transmission today. The different components that make up a fiber cable are the core, cladding, Kevlar®, ferrule, and connector. After assembly, the fiber core is polished and then it is ready to transmit data.

The core is a continuous strand of super thin glass that is roughly the same size as a human hair. It is the center of the fiber cable, and the medium through which light pulses are transmitted. (All CABLExpress fiber optic cables are made with Corning® Bend Insensitive Fiber, the pinnacle of high performance in the industry.)

The core is surrounded by a layer of cladding. The cladding surrounds and reflects light back into the core. Together, the core and cladding make up what is generally referred to as the fiber.

Kevlar® is the registered trademark for the strong synthetic material or yellow ‘hair’ used as a protective outer sheath for the glass fiber core it protects. Its high tensile strength protects the cable from damage when being pulled.

Surrounding the Kevlar is the cable’s jacket or sheathing, which is the outside cover of the cable body. It is most commonly riser (a soft, rubbery plastic called PVC) or plenum (similar to riser, but in the event of a fire, it doesn’t burn as readily, or emit certain toxins in its smoke). The environmental conditions dictate which type of jacket would be best suitable.

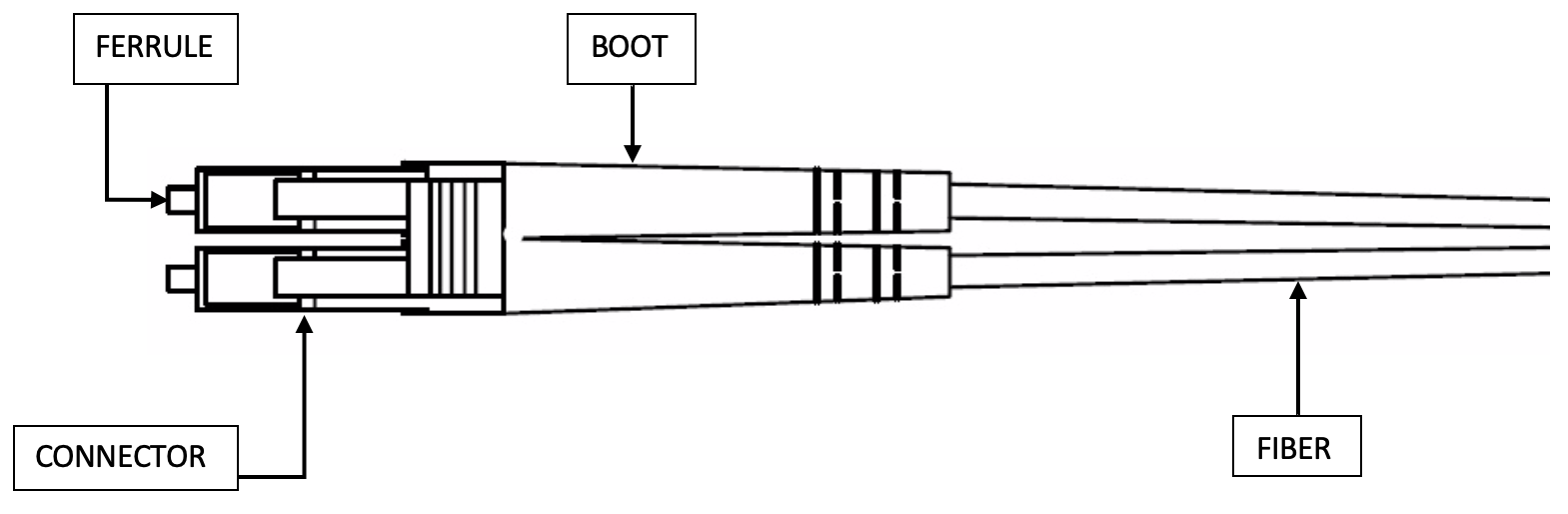

Next up is the boot of the cable. This is the plastic/rubber piece that starts the transition from the cable to the connector. Its purpose is to support the more bendable cable as it leaves the connector, preventing breaks, kinks, and general strain on the cable.

Finally, the connector is the piece that plugs into the equipment. It usually features some kind of locking mechanism, such as a tab. The connector is what most people grab onto when installing or removing a cable.

The ferrule is the protruding portion of a fiber connector. It is often ceramic, plastic or stainless-steel and it houses the end of the fiber to precisely align it for interconnection with the optic transceiver or another fiber.

The fiber is inserted into the ferrule and cemented with an epoxy or adhesive. This gives it long-term mechanical strength and prevents contamination.

The ferrule is the most important and costly part of a fiber connector. If its length, hole centering, and inside/outside diameters are not exact, it results in a poor connection.

It may be tempting to touch the end of the ferrule to see if you can feel the actual fiber. No one should ever do this, as it will leave dirt and oils on the ends of the glass, impeding its ability to transmit data effectively.

The fiber at the end of the ferrule is then meticulously polished to ensure proper data transmission. The fiber must be polished to the proper shape and length so that there is no interruption in the signal.

This is where CABLExpress products truly stand out. The fiber end point is polished with a proprietary process, and then rigorously inspected and tested, resulting in the market’s best possible fiber termination.

Industry standards dictate specific amounts of acceptable data transmission failure (aka “light loss”) in a connection. When you add up these potential loss values for each link in a connection, you have a loss budget.

If your fiber connections exceed your loss budget, you risk losing efficient data transfer. What’s more, as speeds increase, these budgets decrease.

With our superior components and finishing process, CABLExpress fiber products don’t come close to breaking this threshold, while other manufacturers build their products to just barely meet the specification. CABLExpress products are future-proof, and will last for generations of hardware.

CABLExpress features several product lines for fiber jumpers and trunks. As such, depending on the selected line, the cable parts will vary. However, rest assured that we have carefully selected the best components available to ultimately provide the most reliable and accurate fiber optic cables available.

Recent Posts

Low-loss fiber connectivity is essential for...

Starting a data center hardware upgrade is a...

In the rapidly evolving world of data centers,...

Posts by Tag

- data center (12)

- Fiber Optic Cables (10)

- Cabling (7)

- Fiber Optic Cabling (5)

- NETWORKING (5)

- Structured Cabling (5)

- Fiber Cable (4)

- Networking Cables (4)

- Fiber Cables (3)

- Hardware Security (2)

- IT Infrastructure (2)

- Port Replication (2)

- Sustainability (2)

- AI (1)

- Brocade (1)

- Carbon Offsetting (1)

- Data Security (1)

- FCOE Works (1)

- ICLs (1)

- IT Equipment (1)

- IT Network (1)

- IT infrastructures (1)

- POE (1)

- Switches (1)

- Tapped Holes (1)

- data centers (1)

- hardware (1)

- infrastructure (1)

- storage (1)

- strategy (1)

Popular Posts

Why does the gauge matter in my network’s racks?...

High dB loss in fiber optic cabling...

Let’s look at the construction of fiber optic...